Learn How To Screen Print With Catspit Productions, LLC

Squeegee Durometer

Squeegee Durometer And Print Results

This is one of those topics that veteran screen printers may be divided over. Some printers believe that squeegee durometer does not affect ink coverage or opacity. It may not be as important as having the squeegee blade sharp but there are physical properties of squeegee durometers that can affect your print.

In general a softer squeegee will transfer less force and tend to leave the ink on top of the fabric rather than pushing it into the knit. Softer squeegees give more and as a result make the printer stroke accordingly. This is a softer stroke to avoid over bending the flexible squeegee.

In general a softer squeegee will transfer less force and tend to leave the ink on top of the fabric rather than pushing it into the knit. Softer squeegees give more and as a result make the printer stroke accordingly. This is a softer stroke to avoid over bending the flexible squeegee.

Even though the squeegee may be soft and flexible, you do not want to bend the squeegee blade at severe angles.

It should remain almost straight with a slight curve as you stroke. All of this lends to a heavier ink layer being deposited onto the shirt fabric.

Harder squeegees will transfer more of your force to the ink pushing it into the knit much more than a very soft squeegee. Harder squeegees may be easier for beginners to learn with and it is possible to get the same results as with a softer one.

In manual screen printing there are many variables that can affect the print. One of those variables is the manual flooding and stroking of the ink. Whatever squeegee you end up using, it will be your skill in using it that will ultimately be the determining factor in your end results.

The one factor that is very important to the squeegee is the condition of the blade edge. It should be straight, clean, and sharp. There shouldn't be any nicks, grooves, chips or marks at all. A sharp squeegee blade will "sheer" the ink off in the open mesh, with a better deposit, allowing it to pull nicely through the screen.

The one factor that is very important to the squeegee is the condition of the blade edge. It should be straight, clean, and sharp. There shouldn't be any nicks, grooves, chips or marks at all. A sharp squeegee blade will "sheer" the ink off in the open mesh, with a better deposit, allowing it to pull nicely through the screen.

Squeegee durometer is based on a 2 digit number system. The lower the number is, the softer the squeegee will be. 65 durometer is very soft and 95 durometer is very hard. 75 durometer is a common textile squeegee for manual printing.

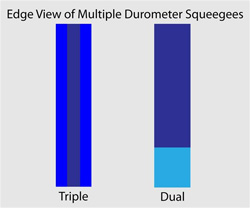

Squeegee comes in different shapes like ball nose, single bevel, and double bevel. The best style squeegee for textile would be rectangular in shape. Squeegee can also vary in the way it is made. Single durometer is the most common. It also comes in dual and triple durometer styles where 2 different durometer squeegees are combined. This gives the squeegee the benefit of having some of the characteristics of each different durometer. For instance, you could have a soft blade part with a firmer over all feel.

To conclude, I would say a sharp blade edge is most important in textile printing. But the very fact that squeegee does come in so many shapes, sizes, and durometers would lead me to believe that technically it does make a difference in what type of squeegee you choose.

Here is a link to an article that supports this and goes into squeegees in much more detail. © 2009 ST Media Group International.

Better Garment Printing through Squeegee Consciousness

Screenprinting Equipment From Catspit Productions

Screenprinting Equipment From Catspit Productions